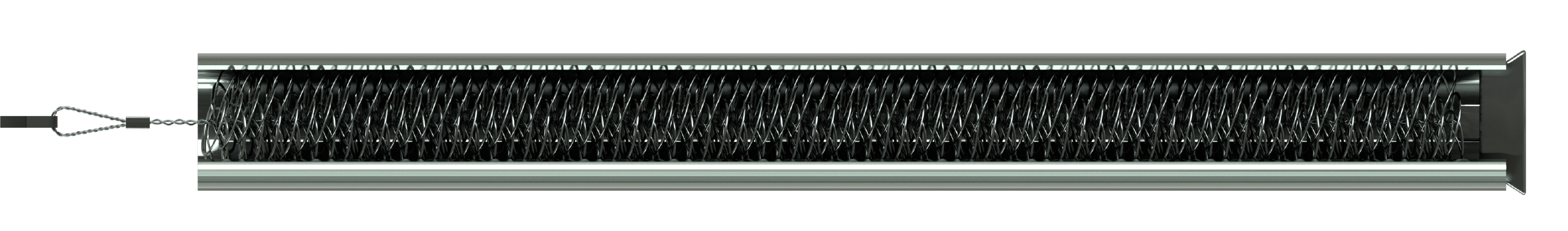

Sure, in overall performance, wire turbulators come in second to rigid soldered turbulators. But when you throw in the usability and ease-of-install criteria into the equation, they’re basically top of the charts. We’ve tested multiple wire turbulator geometries both in-house and in Texas.

We’ve analyzed every possible parameter like loop angle, loop density, twist recurrence, loop wire thickness, central spine integrity at different thicknesses, the works. And it’s given us a goldmine in terms of data at a very large Reynolds operating window all the way down from 10 to 30,000. Allow us to break down the data-gather and correlation development protocols involved in making this ratable within compatible software platforms.

Multiple geometries were tested in a side-by-side with a no-turbulator case. Each geometry has its own part ID. The Reynolds range covered was between 10 and 30,000. The data for each part ID was tested and verified. A test report was created for each part ID with correlations to calculate heat transfer and pressure drop. Those correlations are then picked up by our VorTX DLL that has been made for us which will tell the user the Part ID that will solve their heat transfer problem for them. Users can use the VorTX DLL in one of two ways:

A. Users can put in a pressure drop constraint and the software will throw out the best possible performance available at that pressure drop. It will spin out a Part ID. That Part ID is what the user needs to send CEI for running up a quote or potential order.

B. Users can input a part ID they’ve used previously and see how it’ll perform for the case they’re currently working on. The

Part ID can again be sent to CEI to either run up a quote or potential order.

1. Any application where the tubeside is the limiting factor like oil or glycol coolers. In some cases, even water, where the other side is Steam.

2. Where fouling mitigation through increasing shear stress is possible.

3. In vaporizers plagued with issues like film boiling and mist flow. Further, enhancing bubble cutting will also help with overall HTC improvement.

4. Draining condensate from the wall to allow for more area for condensation in vertical condensers. The geometry can be angled in a way where the loops take the fluid from the wall and drain it through the center

For software users, write in with a request for VorTX.DLL. That will allow users to simply input the pressure drop allowance as a constraint to have the software determine the best part ID available that will give the max performance for that pd allowance. Users can also input a part ID they have and see how it will perform for a particular use case.

For non-software users, you can send your datasheet and we’ll model it in software and send you a pdf output summary.

Possible Refinery Performance Monitoring Software Integration: This will allow users to look at the possible improvement in furnace inlet temp by the addition of turbulators in one or more heat exchangers and the cross impact that performance will have on the overall furnace inlet temp. The data from our tests in Texas can be hard coded into the software to show even fouling mitigation using the shear stress principle.

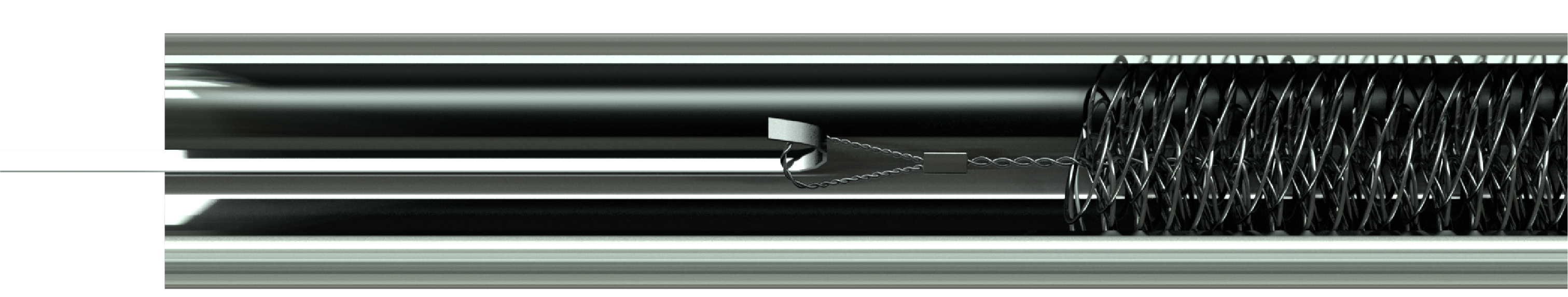

There is a pull hook at one end. Simply insert wire through the tube from the outlet to inlet side and then use the wire to grapple onto the hook and pull the turbulator through the tube in the direction of the fluid flow, the anchor will then hit the tube once insertion is complete.

There are two anchor types. Plate Anchors with a flat head. Plate Anchors with a non-flat head. The anchors will be sized so that they can pass through the plug header ID but stop short of passing through the tube ID.

Tube Size Ranges with Data Backing: 3/8 inch, ½ inch, 5/8 inch, 0.75 inch, 1 inch, 1.25 inch and 1.5 inch.

Tube Size Ranges without Data Backing: We can make turbulators as small as ¼ inch and as large as 1.5 inches.

VorTX is Concept Engineering International’s dynamic link library (DLL) developed by HTRI under proprietary contract with Concept Engineering International. Multiple Concept Engineering International turbulators (wire and spiral tube inserts) were tested at HTRI’s Research and Technology Center in Navasota, Texas, USA. The VorTX DLL contains tube side single phase heat transfer and pressure drop correlations for modeling Concept Engineering International’s products which were developed under proprietary contract with HTRI using Concept Engineering International’s proprietary data. HTRI used laminar flow CFD results to supplement empirical testing measurements at Reynolds numbers under 500.

The VorTX DLL can be used with HTRI Software for the following purposes:

1. Identifying an optimal Concept Engineering International product from those supported by the VorTX DLL based on utilizing the maximum amount of pressure drop allowed.

2. Evaluating the performance of a Concept Engineering International product supported by the VorTX DLL that resembles the geometry of those tested by HTRI.

We’re looking for the best operating window for our products from a Reynolds standpoint.

We’re diving deep into wall correction factor impact of our geometries in software outputs.

We’re looking at the additional hydraulic load of each geometry. Small tweaks in angles of attack. How much the shear stress is when you pit turbulator vs bare tube. What the impact on fouling is likely to be because of that additional wall sheer stress.

How we can disrupt film boiling to move over to nucleate boiling, arrest mist flow and reduce bubbles down to size.

Our turbulator range (multiple geometries) has been tested for a hard data mining operation. Post that, the data has been analyzed and curve fitted and then modeled into correlations along with a test report for each insert geometry.

We’ve also done supplemental CFD work via a proprietary contract to home in on more accuracy.

To completely integrate into software platforms, we’ve also had developed the VorTX.DLL plugin that will hold this data and allow you, the user, to design your exchangers using our products in a matter of seconds if you’re using compatible software.

If you’re an end-user like a refinery who uses a performance monitoring software, we’re also looking at hard coding our mined data in software such as this to see the impact we can have on refinery exchangers to mitigate fouling by looking at shear stress increases and what that will mean for overall CO2 emissions reduction.