Twisted tape turbulators are the most universally used and understood turbulator type. The reason is that these have been tested by multiple people and their correlations (almost open-source) are hard coded into multiple software platforms giving a reliable measure of htc and pd improvement.

In terms of performance rankings, they come in fourth in our range. And this is a fair comparison as the data we have on the other turbulator types mined in Texas leads us to that conclusion.

The important thing is L/D conformance as the prime factor for performance and pressure drop is the twist ratio.

Twisted tapes will give you the lowest pressure drop in our range and the neat thing is that we can also make asymmetric twisted tapes. Asymmetric tapes are nothing but twisted tapes where the L/D can be varied over the length of the tube.

1. Any application where the tubeside is the limiting factor (like oil or glycol coolers).

2. Where fouling mitigation on account of increasing shear stress is possible.

3. In vaporizers plagued with issues like film boiling and mist flow. Further, enhancing bubble cutting will also help with overall HTC improvement.

Possible Refinery Performance Monitoring Software Integration: Users can look at the possible improvement in furnace inlet temp by the addition of twisted tape turbulators in one or more heat exchangers and the cross impact that performance will have on the overall furnace inlet temp. This can show up as a performance improvement both in heat transfer and as a reduction in fouling on account of the shear stress principle.

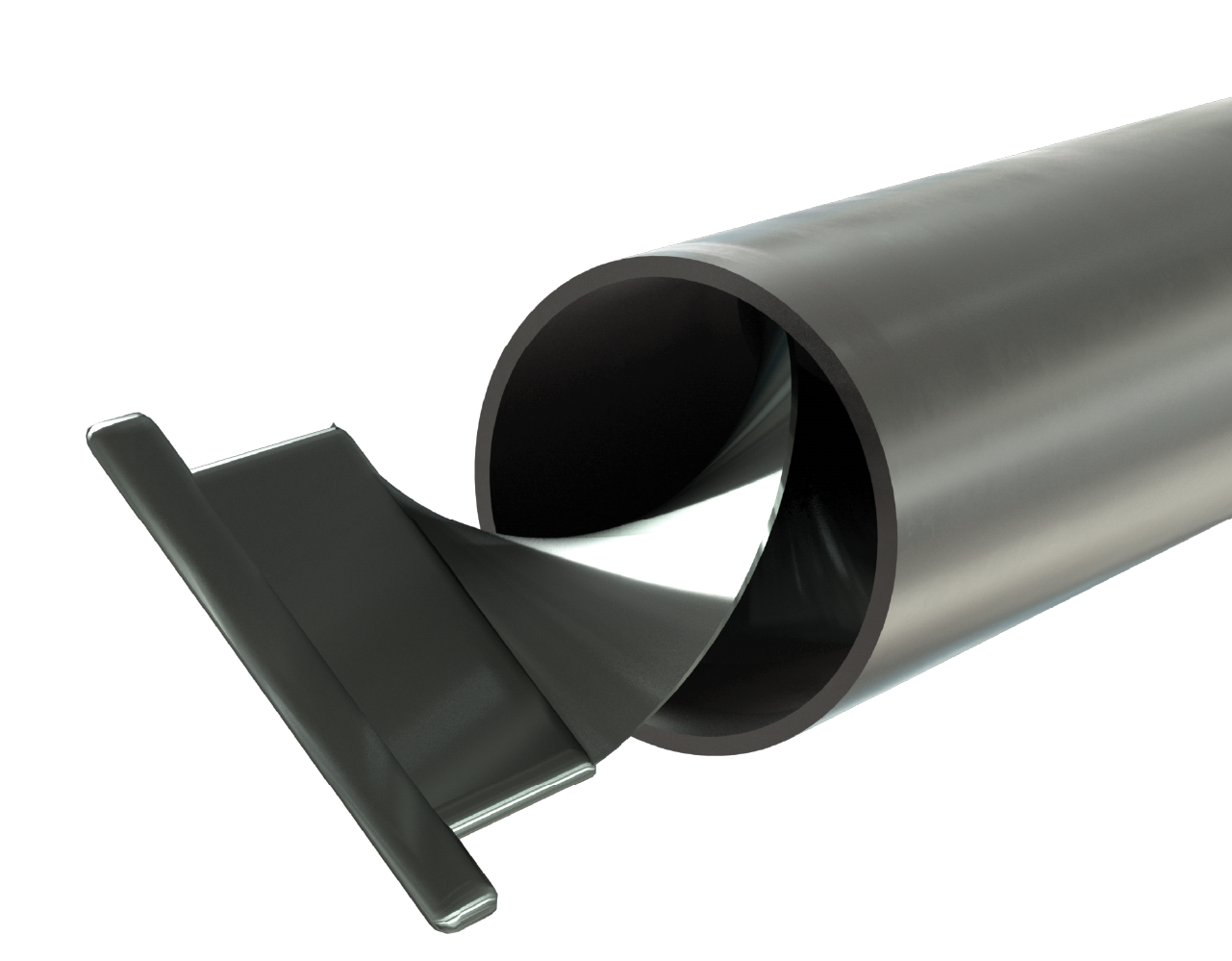

Simply push a long piece of wire through the tube and hook it into the hole provided at one end of the twisted tape. Pull it through the tube till the anchor hits the tube OD. Twisted tapes have two anchor types. Plate Anchors and Notch Anchors.

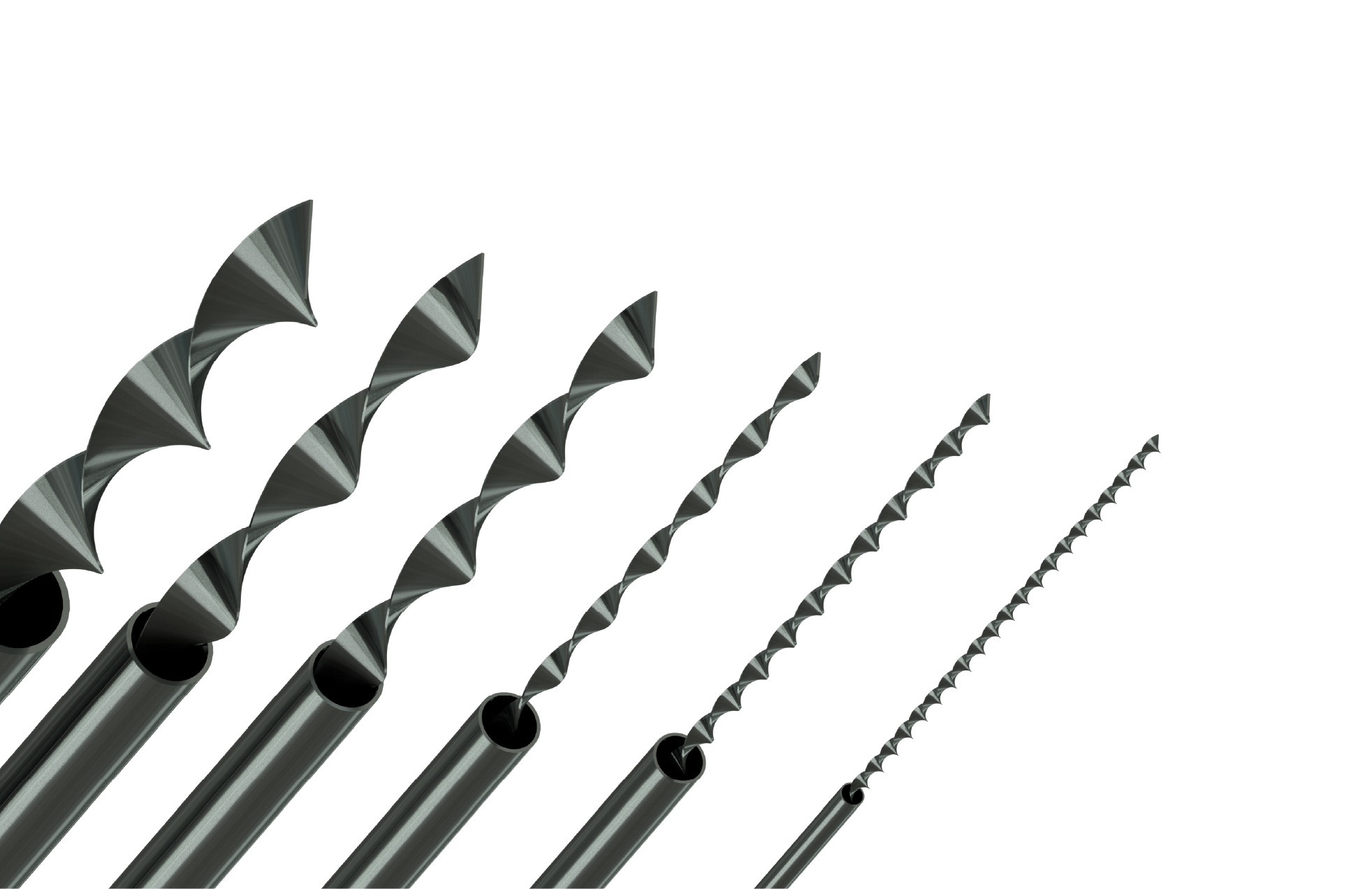

Tube Size Ranges with Data Backing: ¼ inch, 3/8 inch, ½ inch, 5/8 inch, 0.75 inch, 1 inch, 1.25 inch, 1.5 inch, 2 inch and 3 inch.