They come in at the #1 spot by a fair distance.

The reason for this is twofold but to understand that we have to first understand their construction and install method.

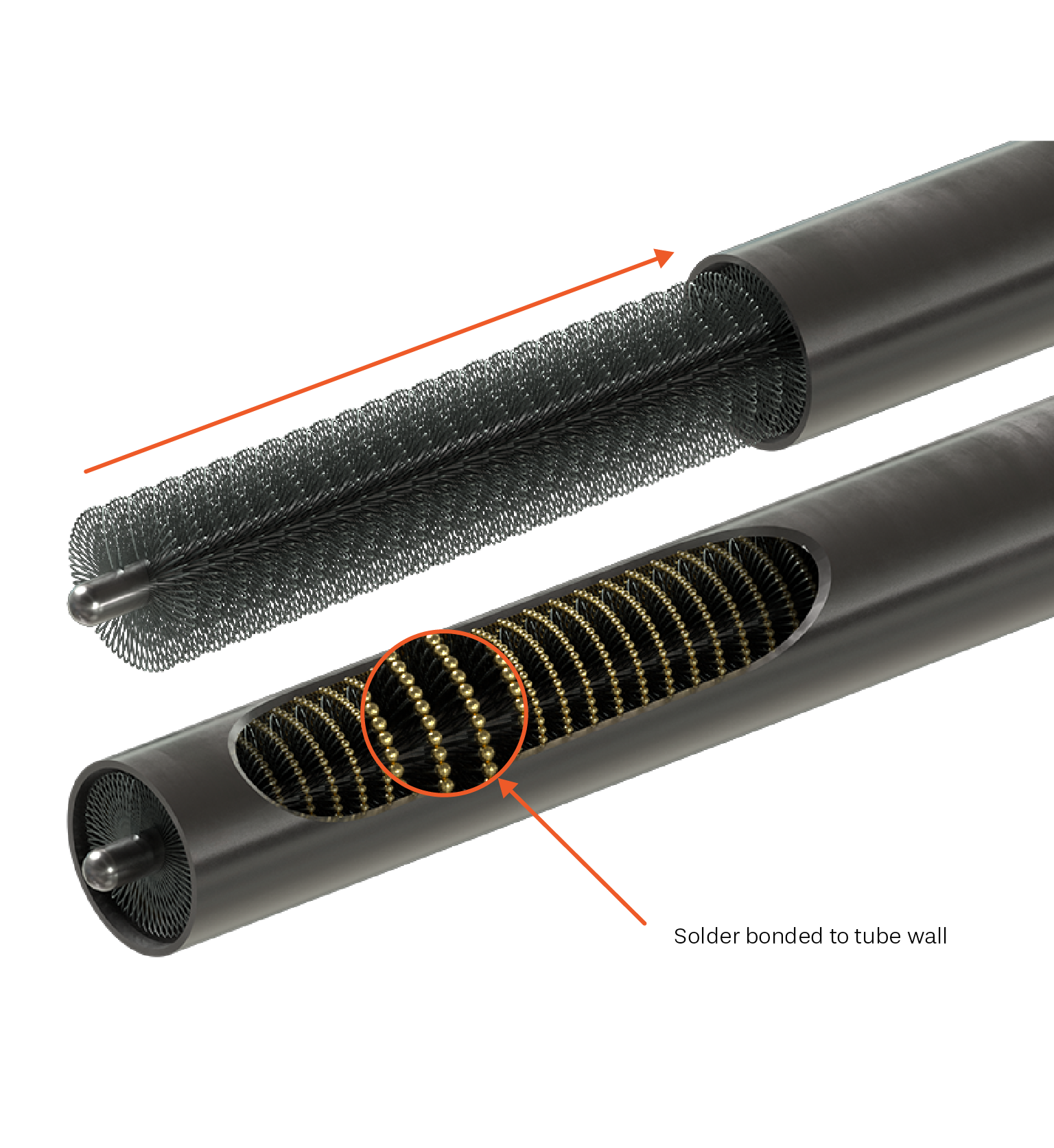

Rigid soldered turbulators have a central rod on which are soldered wire loops. The entire turbulator is then installed inside the tube where the wire

loops are soldered to the inner tube wall.

So, the twofold reason for why they occupy top spot in the performance rankings is:

1. They offer convective heat transfer on account of the wire loops turbulating the fluid flow and breaking the boundary layer by creating vortices much like a wire turbulator. However, the packing density of loops on rigid soldered turbulators from a manufacturing standpoint can be a lot higher than wire turbulators. And the net free flow area is a lot lower increasing velocity.

2. They offer conductive heat transfer as the solder bonding of the wire loops to the turbulator and to the inside of the tube acts as a surface area xtension making it perform like an internal fin tube. This massively increases the Ai (Internal Surface Area) and in turn, the actual U (Overall HTC).

The area increase ranges from 2x to 4x depending on the config chosen.

While the pressure drop is also the highest as compared to other turbulator types, the overall performance is unmatched. Something to really think about is, if you take the same loop count of a rigid soldered turbulator and a wire turbulator, the pd would be level pegging for the most part but you’d also get a massive bump in free performance (performance without an increase in pd) over the wire urbulator because of the bonding effect making it an internal surface area extension play.

Typically, ordering these involves ordering the tubes and turbulators soldered to them by us.

Big Use Cases

1. Super viscous oil coolers.

2. Air Intercoolers.

3. Any viscous fluids that could use both conductive and convective heat transfer bumps.

Design Method

To design using Rigid Soldered Turbulators, please send us your design file (native to the software you use) or a data sheet of your exchanger and our design team will create a rating based on our legacy data. Rigid Soldered Turbulators have not been tested in Texas by CEI but run very close to actual performance experienced on-site.

Zero Assembly Installation

These are solder bonded to the inside of the tube, they come pre-installed by CEI inside the tube required.

Retention Method

Since they’re solder bonded, they’re fixed in place and will not move forward with fluid flow. It’s why we don’t need anchors or any other retention methods.