The Twisted Tape Turbulator albeit simple is extremely effective. The fact that its design parameters are well known and built into major heat transfer software is what makes it the most widely used turbulator there is. It consists of a metal strip formed with a precise twist count and profile to deliver turbulation by redirecting the fluid in a concentric path. This is often the ideal turbulator for retrofitting existing equipment to improve heat transfer efficiency.

Swirl Action Flow for continuous antifouling action.

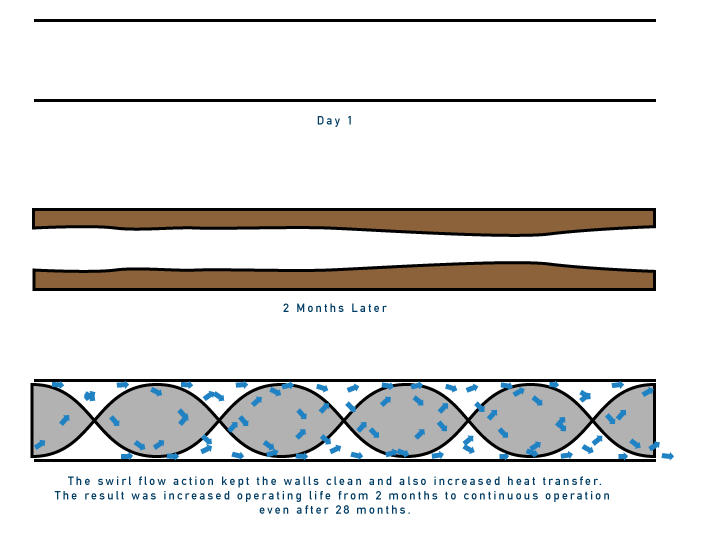

Heat transfer apart, the twisted tape has a unique tumble effect of the fluid within the tube where in a “swirl flow action” it churns the fluid from the center of the tube to the wall. This action prevents and maybe removes scale buildup on the walls.

To give you an idea of the scale of this action, consider a fluid with a flow rate of 1.5 metres per second. If the twisted tape has 10 turns per meter this equals a speed of 1.5 x 10 x 60 = 900 revolutions per minute. You can think of it as 900 RPM. We have used this technique successfully at refineries. The following is a case study.

Case Study

700 tons per hour crude/residue exchanger A/B in presalter preheat train at a major refinery in Java, Indonesia.

- The rate of fouling was very rapid and the crude temperature used to fall from 270° to 248° in 2 months.

- The refinery used to have to stop the exchanger and run hot kerosene in reverse through it to clean the fouling.

- Our turbulators were installed in May 2016 and the equipment has been in continuous operation till the time of writing (April 2018) without the need for kerosene cleaning.

- We are happy to partner with refineries in designing and implementing the perfect solution to this fouling issue.